Sealing Solutions for Hydraulic Air Systems

The best sealing system for your application

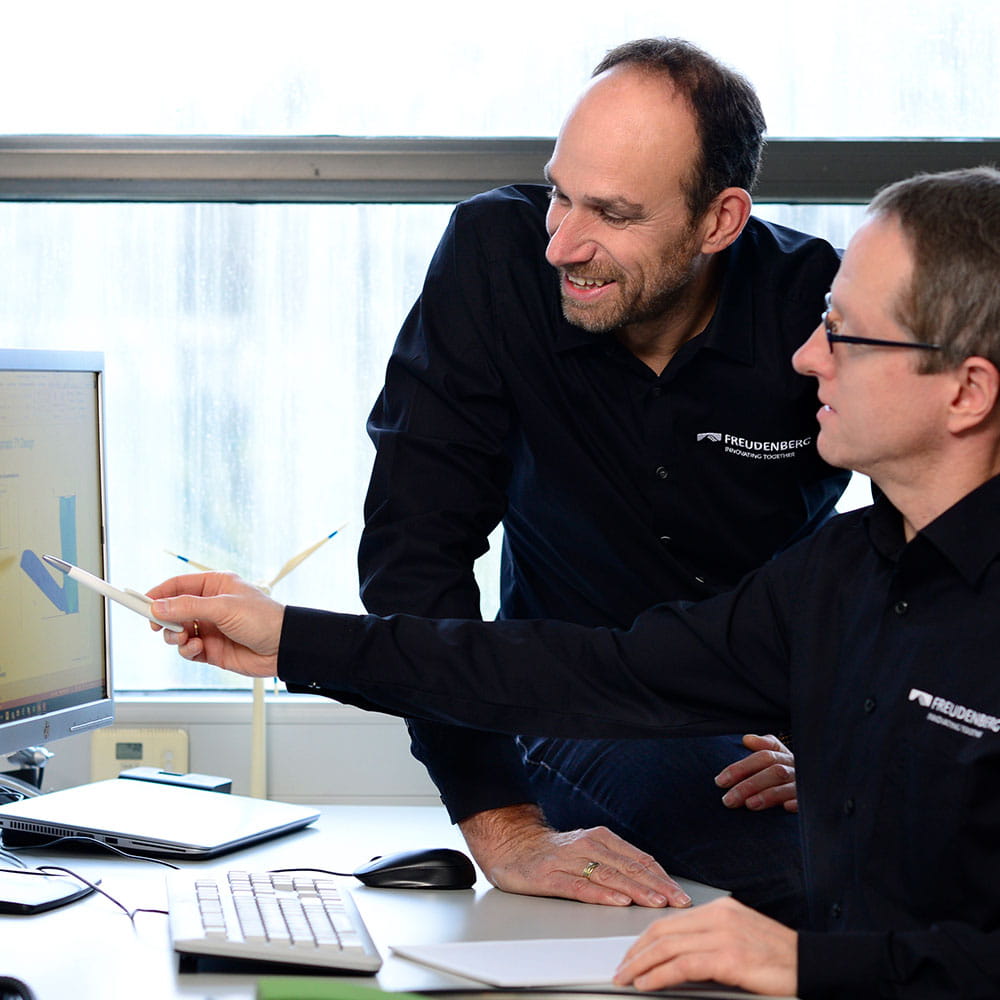

A hydraulic sealing system is an extremely complex tribological system that has many influencing parameters that require close consideration. These include the oil used, the surfaces of the rods, and the application parameters such as pressure, temperature, speed, dirt ingress, and frequency of use, for example. Our sealing experts will assist you in analyzing your specific application parameters and in selecting the right sealing systems for sealing a wide variety of hydraulic / pneumatic applications. Based on our many years of experience and extensive material expertise, we use state-of-the-art FEM calculation models to depict material behavior.

If necessary, we offer training courses specially adapted to individual customer needs – at your premises or at one of our plants – that enable our customers to deepen their knowledge of all aspects of sealing technology.

Learn more about Sealing Solutions for Use in Hydraulic Applications

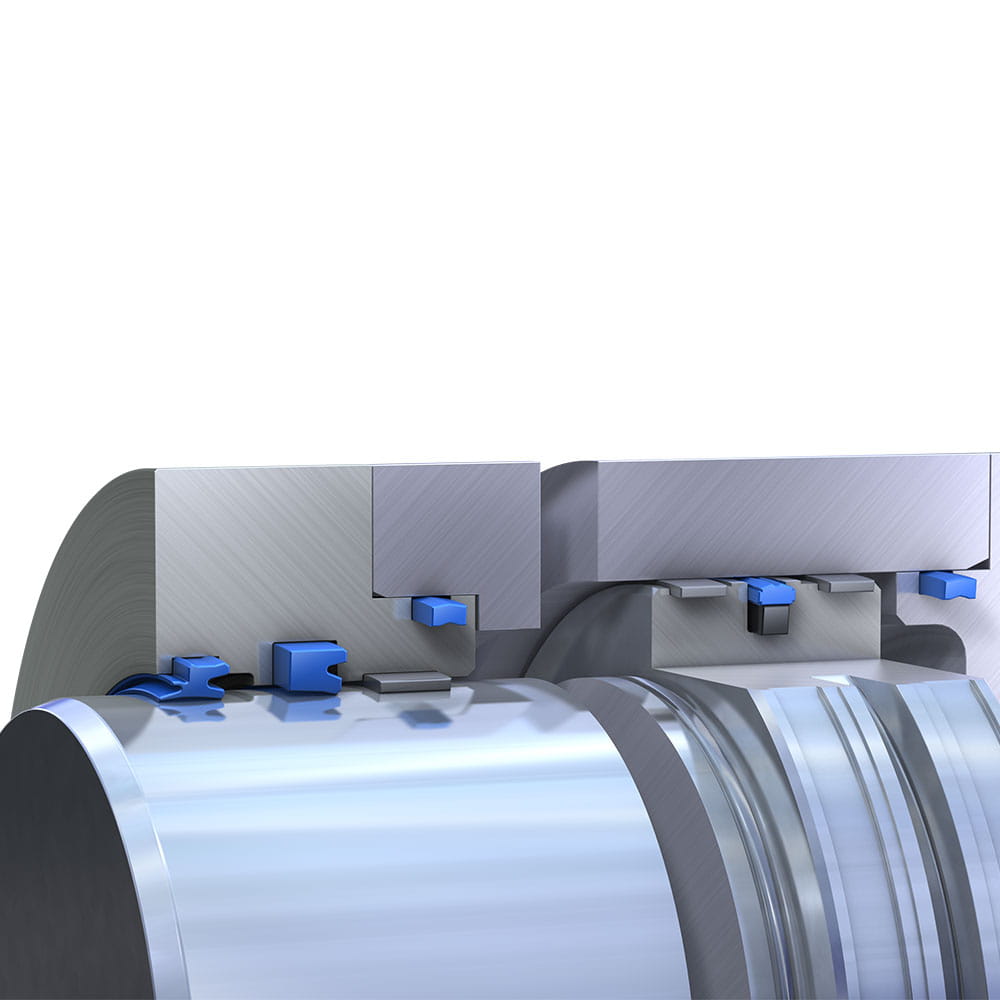

Detailed study of the interaction in the sealing system

Extensive detailed knowledge of the application and its interaction in the tribological system is indispensable for selecting the optimally suitable sealing system. Our experts use a wide range of methods to analyze the individual sealing elements in the sealing system, the rods, pistons and tubes of a cylinder, and the chemical compatibility of the material-lubricant combination used.

The comprehensive analysis also includes the macroscopic and microscopic examination of the sealing edges. Here, not only the geometric condition of the sealing edge can be recorded, but also the local physical and chemical properties. The same applies to the mating parts in the sealing system.

The service life of the sealing system is largely determined by the lubricant supply in the sealing gap. How the aging of sealing materials and lubricants influence each other can be determined more precisely in advance by performing specific investigations. This facilitates the selection of suitable design elements and contributes significantly to the reliable functioning of the sealing system over a long service life.

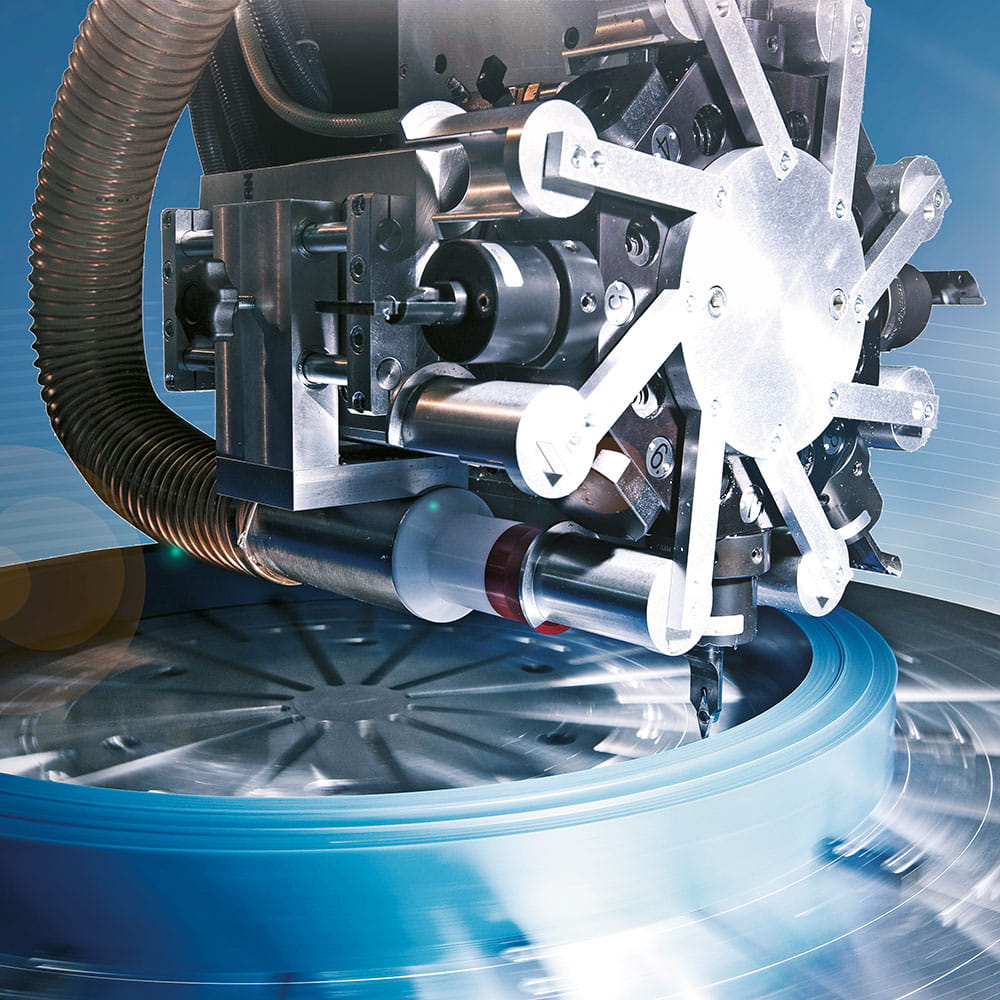

Testing under real conditions shortens development cycles

Testing hydraulic and pneumatic sealing systems under conditions similar to those of the real application strongly contributes to shortening development times. For this reason, we offer our customers a comprehensive portfolio of customized tests to identify the best sealing systems for their process. This includes, for example, tests to determine the service life of seal-lubricant combinations, friction tests, and high- and low-temperature tests.

Our services include:

Test facilities such as a rod seal test bench, a piston seal test bench and extensive laboratory equipment are available for all these investigations.

Learn more about Test Benches for Cylinder Application

Short development times thanks to Freudenberg Xpress®

To keep development times short and initial investments economical, our sealing experts call on the services of Freudenberg Xpress® for sampling. Freudenberg Xpress® offers a large portfolio of CNC-turned sealing solutions made from original Freudenberg materials. This allows fast and flexible production not only of prototypes of standard seals but also of customized solutions that meet the highest quality requirements.

Learn more about Rapid Prototyping

Sealing Solutions for Hydraulic Air Systems

Source: https://www.fst.com/services/design-and-engineering/evaluation-of-sealing-systems/hydraulic-sealing-systems/